- A+

提示:以下文章由有道机器人翻译:Teknor Apex介绍Monprene®OM化合物,与当前的TPE相比,具有成本和加工优势,加上一个新的在线资源的TPE包覆成型。

Teknor Apex公司的新一代热塑性弹性体(TPE)过塑复合材料与更广泛的工程热塑性塑料具有更强的附着力,更容易成型,比该公司以前提供的同类复合材料更经济。此外,该公司还推出了over塑学院(the over塑学院),这是一个新的在线资源,用于在over塑中使用TPEs。

Monprene®OM化合物是基于先进的粘附改性技术,当覆盖在刚性聚合物上时,可以提高粘结强度,这些聚合物用于消费品、小家电、电动工具和其他需要“软/硬”材料组合的组件。有四个系列的标准等级可供选择,每一个都设计用于附着特定的基板材料。Teknor Apex还可以开发定制配方,以满足特定的客户要求。

“这些新一代包覆成型TPEs比我们早期的产品更热稳定,”消费产品高级市场经理Hilarie Rubin指出。Monprene OM化合物可以在更高的温度下成型,这更有利于获得良好的附着力。

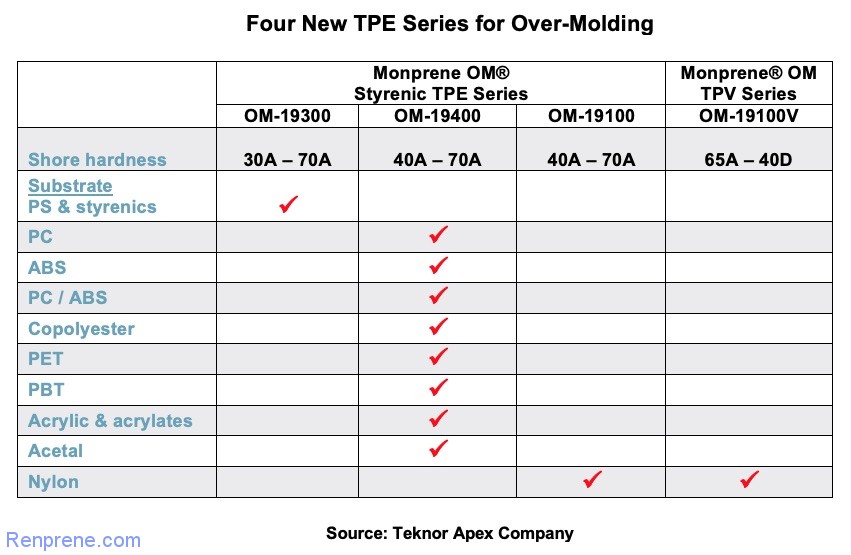

四个新标准系列中有三个是基于苯乙烯TPE技术,并在握把、手柄和其他“软触摸”部件上表现出良好的干触觉性能。第四是基于TPV (EPDM + PP)技术提高耐化学性。见下文:

●Monprene om - 19300。该化合物的硬度范围为30至70 Shore a,专为粘附于通用和高冲击聚苯乙烯和苯乙烯共聚物,如甲基丙烯酸酯-丁二烯-苯乙烯(MBS)。

●Monprene om - 19400。该通用系列硬度范围从40到70 Shore A,可以覆盖到非常广泛的工程热塑性基板上,其中一些是聚碳酸酯(PC), ABS, PC/ABS共聚酯,PET, PBT,丙烯酸(PMMA),丙烯酸共聚物(PSA, ASA和SAN),和缩醛(POM)。

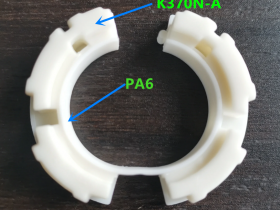

●Monprene om - 19100。该系列产品具有压缩变形小、手感干燥等特点,适用于尼龙包覆成型。硬度范围从40到70肖氏A。

●Monprene om - 19100 v。像OM-19100系列,该系列由低压缩集化合物设计的尼龙6,66,12等,但它也表现出增强的化学抗性。硬度范围从65 Shore A到40 Shore D。

“利用我们在制造TPE和工程热塑性化合物方面的经验,Teknor Apex开发了新一代TPE,可与最广泛的聚合物结合,”Ms. Rubin说。“我们的专家团队在法规和产品安全合规方面为这些产品提供支持,我们的产品开发设施用于零部件设计、工装和附着力测试,我们的移动工程团队协助流程优化。”

Teknor Apex推出了一个名为“包覆成型学院”(www.teknorapx.com/overmolding-academy)的新网页。“我们把它设计成TPE包覆成型的头号资源,”鲁宾女士说。“访问者可以找到博客、白皮书和指南,帮助寻找合适的材料,协助产品和工具设计,以及流程优化。”

New-generation thermoplastic elastomer (TPE) overmolding compounds from Teknor Apex Company exhibit greater adhesion to a wider range of engineering thermoplastics, mold more easily, and are more economical than comparable compounds previously available from the company. In addition, the company has launched The Overmolding Academy, a new online resource for use of TPEs in overmolding.

Monprene® OM compounds are based on advanced technologies for adhesion modification that exhibit improved bond strength when overmolded onto rigid polymers used in consumer product, small appliance, power tool, and other components requiring “soft / hard” material combinations. Four series of standard grades are available, each designed to adhere to specific substrate materials. Teknor Apex can also develop custom formulations to meet specific customer requirements.

“These new-generation overmolding TPEs are more thermally stable than our earlier products,” noted Hilarie Rubin, senior market manager for consumer products. “Monprene OM compounds can be molded at higher temperatures, which are more conducive to obtaining good adhesion.”

Three of the four new standard series are based on styrenic TPE technology and exhibit dry haptics for good tactile properties in grips, handles, and other “soft-touch” components. The fourth is based on TPV (EPDM + PP) technology for improved chemical resistance. See below:

● Monprene OM-19300. Grades range in hardness from 30 to 70 Shore A. The compounds are designed for adhesion to general-purpose and high-impact polystyrene and styrenic copolymers such as methacrylate-butadiene-styrene (MBS).

● Monprene OM-19400. This general-purpose series ranges in hardness from 40 to 70 Shore A and can be overmolded onto a very broad range of engineering thermoplastic substrates, some of which are polycarbonate (PC), ABS, PC/ABS blends, copolyester, PET, PBT, acrylic (PMMA), acrylate copolymers (PSA, ASA, and SAN), and acetal (POM).

● Monprene OM-19100. Characterized by low compression set as well as dry haptics, this series is designed for overmolding onto nylon. The hardness range is from 40 to 70 Shore A.

● Monprene OM-19100V. Like the OM-19100 Series, this series consists of low compression set compounds designed for overmolding onto nylon 6, 66, 12, etc., but it also exhibits enhanced chemical resistance. The hardness range is from 65 Shore A to 40 Shore D.

“Drawing on our experience in manufacturing both TPE and engineering thermoplastic compounds, Teknor Apex has developed a new generation of TPEs that bond to the widest range of polymers,” said Ms. Rubin. “We support these products with our team of experts in regulatory and product safety compliance, our product development facilities for part design, tooling and adhesion testing, and our mobile engineering team to assist in process optimization.”

Teknor Apex has launched a new web page called The Overmolding Academy (www.teknorapex.com/overmolding-academy). “We’ve designed this to be the number one resource for TPE overmolding,” said Ms. Rubin. “Visitors can find blogs, whitepapers and guides to help source the right materials and assist in product and tooling design, as well as in process optimization.”

- TPV/TPE业务助理

-

- 更多好文敬请关注

-