- A+

Nylabond™TPE热塑性弹性体的设计远不止是粘结尼龙基材;它们在设计时考虑到了特定的性能要求。

Nylabond™6091

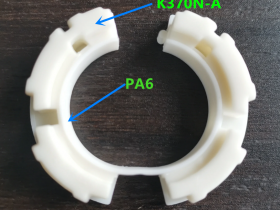

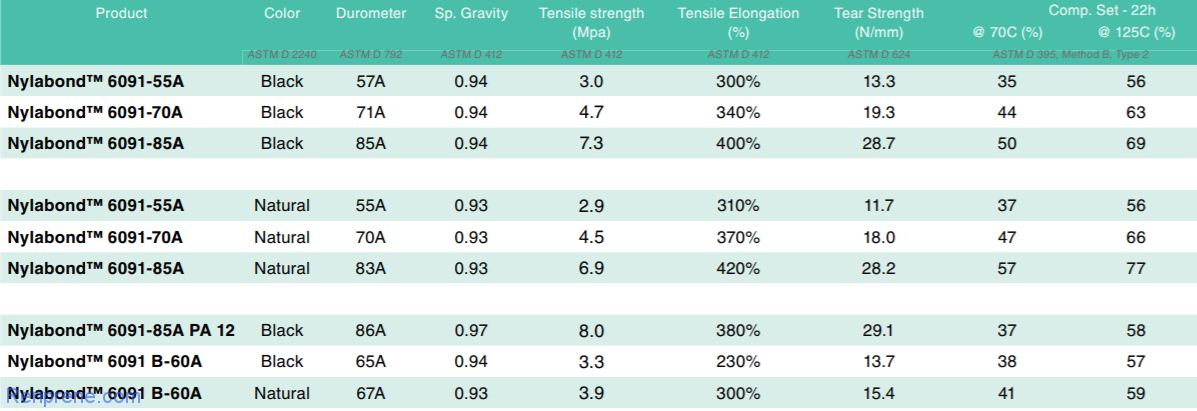

基于tpv的Nylabond™6091系列材料为尼龙过塑应用的性能设定了标准。其硬度范围从55A到85A,通常用于汽车、运输和高要求的工业应用。这些材料不仅对尼龙基材具有很强的附着力,而且还具有优异的耐化学性、耐油性、耐候性和高低温性能。Nylabond™6091材料获得了广泛的全球汽车认证,这证明了它们的长期性能,也简化了PPAP提交。Nylabond™6091材料备有天然和黑色两种即时可用。

韧性哥注:NYLABOND 6000系列使用了santoprene TPV的基料,美特K300-A8系列可以取代。

Nylabond™7091

我们的Nylabond™7091系列是为了处理长期暴露在高温和流体浸泡下,使其成为世界上性能最好的热塑性弹性体。Nylabond™7091可以长期暴露在最具腐蚀性的汽车液体中——发动机油、传动液和润滑脂——以延长车辆的寿命,即使这些液体是热的。为容易的热塑性塑料加工,包括吹塑成型,注塑成型,overmolding, Nylabond™7091材料适合广泛的应用,包括汽车靴,传动部件,排气管密封,进气管道和更换空气冷却器管道,以及隔振器和支架。Nylabond™7091材料可用黑色自由流动颗粒包装在50磅(22.7公斤)防潮袋。

推荐阅读:韧性哥:尼龙包胶热塑性弹性体选择指南

Nylabond™ TPE compounds were designed for far more than just bonding to nylon substrates; they were engineered with specific performance requirements in mind.

Nylabond™ 6091

TPV-based Nylabond™ 6091 series materials set the standard for performance in nylon overmolding applications. Available in hardnesses ranging from 55A to 85A, they are commonly used in automotive, transportation, and demanding industrial applications. These materials not only provide strong adhesion to nylon substrates, but also exhibit excellent chemical and oil resistance, weatherability, and high and low temperature performance. Nylabond™ 6091 materials carry a wide range of global automotive approvals, which demonstrates their long-term performance capability and also simplifies PPAP submissions. Nylabond™ 6091 materials are stocked for immediate availability in both natural and black.

Nylabond™ 7091

Our Nylabond™ 7091 Series is formulated to handle long-term exposure to high temperatures and fluid immersion, making them some of the world’s highest performing thermoplastic elastomers. Nylabond™ 7091 can withstand long-term exposure to the most aggressive automotive fluids – engine oil, transmission fluid, and lubricating greases – for the life of the vehicle, even when those fluids are hot. Developed for easy thermoplastic processing, including blow molding, injection molding, and overmolding, Nylabond™ 7091 materials suit a wide range of applications, including automotive boots, transmission components, exclusion seals, air intake ducts and change-air cooler ducts, as well as vibration isolators and mounts. Nylabond™ 7091 materials are available in black free-flow pellets packaged in 50 lb.(22.7kg) moisture-barrier bags.

Automotive Approvals

- GMW 15817 Type 1

- GMW 15817 Type 2

- MSAR* 100 AAN

- MSAR* 100 BAN

- MSAR* 100 CAN

* The MSAR specifications are Stellantis

- VW 50123 Conformance

- Daimler DBL552.30 Conformance

- SAE J200 callouts

- ASTM D4000 callouts

- TPV/TPE业务助理

-

- 更多好文敬请关注

-